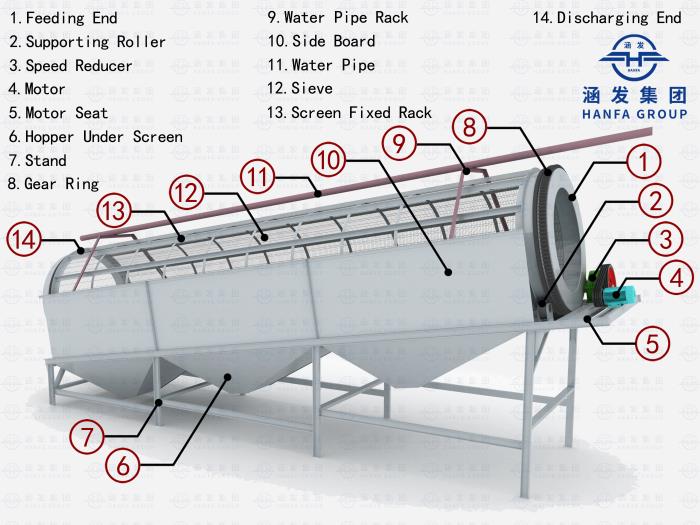

Working principle

In order to improve the screening efficiency, the speed of material moving in the trommel screen should not be too fast, otherwise it will cause insufficient and incomplete screening. Therefore, the trommel screen generally has a strictly specified installation inclination angle. Generally speaking, the angle is 5°. In actual situations, adjustments can be made as needed.

The drum section is connected to the trommel screen turntable through nuts and screws, so the installation and disassembly of the drum section is more convenient. Since the drum segment is connected with the turntable, when the turntable rotates under the drive of the driving device, the drum segment also rotates together.