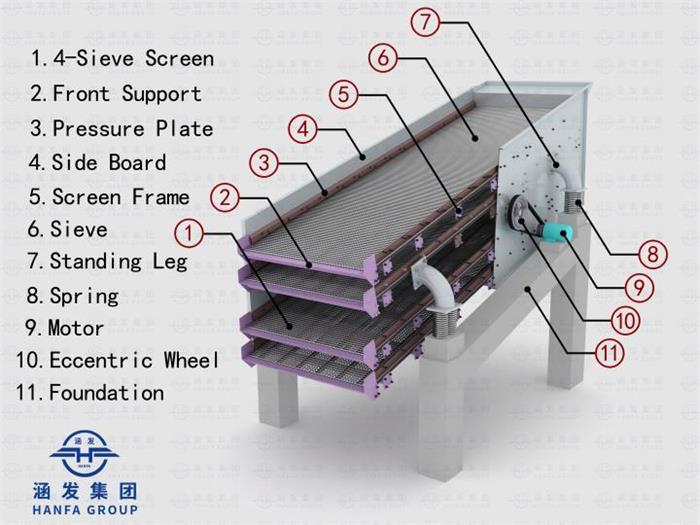

The vibrating screen moves in a circular motion with multiple layers and high efficiency. The vibrating screen is designed with the barrel type of eccentric shaft vibration exciter and eccentric block to adjust the swing. It is manufactured with long material screen rifling and many screen specifications.

Answer customer questions professionally

Combined with the actual configuration plan

Regular return visit and testing

Hammer Crusher is a must-have machine in wide range of fields like mining, quarrying, and construction industries.

He eccentric block of the exciter is driven by the motor via the triangle belt to rotate at high speed. The rotary eccentric blocks produce great centrifugal force which forces the screening box to move in circles with certain amplitude. Materials on the leaning screen surface are impacted to continuously do casting or throwing motions. Small particles pass through the screen holes of circular vibrating screen when meeting the screen surface, thus completing the separating process.

The circular vibrating screen is a high-efficiency and new-type vibrating screen featured by circular vibration and multi-layers This type of vibrating screen is specially designed for screening material stone of a quarry, and widely used for product classification in mining, building materials, transportation, energy, chemical products industries. So, it’s a kind of ideal equipment used in the crushing and screening unit. If the screen with small boring diameter is installed, the wet and sticky material can not be screened unless the water spraying method is used.

| Model | Screen Size(mm) | Number of Layers | Screen Area(㎡) | Capacity (m³/min) | Dip(°) Angle | Power (kw) | Dimension (L×W×H)(mm) | Weight (t) |

| 2YK1245 | 1200×4500 | 2 | 5.4 | 25-206 | 15 | 11 | 4872×2610×2520 | 4320 |

| 3YK1245 | 1200×4500 | 3 | 5.4 | 35-206 | 20 | 11 | 5155×2684×3754 | 4460 |

| 2YK1535 | 1500×3500 | 2 | 5.25 | 34-200 | 15 | 11 | 4684×2971×2404 | 3355 |

| 3YK1535 | 1500×3500 | 3 | 5.25 | 34-200 | 20 | 15 | 4719×3106×3273 | 5710 |

| 1YK1545 | 1500×4500 | 1 | 6.75 | 44-258 | 20 | 11 | 4806×2911×2076 | 3900 |

| 2YK1545 | 1500×4500 | 2 | 6.75 | 44-258 | 20 | 15 | 4650×2820×3500 | 4370 |

| 3YK1545 | 1500×4500 | 3 | 6.75 | 44-258 | 15 | 15 | 5650×3000×3800 | 4832 |

| 3YK1548 | 1500×4800 | 3 | 7.2 | 47-275 | 20 | 15 | 5011×3986×2653 | 6070 |

| 4YK1548 | 1500×4800 | 4 | 7.2 | 47-275 | 20 | 18.5 | 4800×2947×4045 | 7090 |

| 1YK1848 | 1800×4800 | 1 | 8.8 | 56-330 | 20 | 15 | 4904×3020×2943 | 7122 |

| 2YK1848 | 1800×4800 | 2 | 8.8 | 56-330 | 20 | 15 | 4802×3009×2860 | 6189 |

| 3YK1848 | 1800×4800 | 3 | 8.8 | 56-330 | 20 | 22 | 5066×3986×2969 | 6935 |

| 2YK1854 | 1800×5400 | 2 | 9.72 | 63-586 | 20 | 22 | 5200×3400×3911 | 7602 |

| 3YK1854 | 1800×5400 | 3 | 9.72 | 63-586 | 20 | 22 | 6200×3326×3593 | 8640 |

| 4YK1854 | 1800×5400 | 4 | 9.72 | 63-586 | 15 | 30 | 5447×3417×4266 | 10530 |

| 1YK2154 | 2100×5400 | 1 | 11.3 | 73-683 | 15 | 18.5 | 5400×3547×4266 | 5269 |

| 2YK2154 | 2100×5400 | 2 | 11.3 | 73-683 | 20 | 22 | 5400×3650×3856 | 7851 |

| 3YK2154 | 2100×5400 | 3 | 11.3 | 73-683 | 20 | 22 | 5590×3600×3900 | 9857 |

| 2YK2160 | 2100×6000 | 2 | 12.6 | 81-720 | 20 | 30 | 6375×3821×3707 | 9240 |

| 3YK2160 | 2100×6000 | 3 | 12.6 | 81-720 | 20 | 30 | 6453×3821×4907 | 12757 |

| 4YK2160 | 2100×6000 | 4 | 12.6 | 81-720 | 20 | 45 | 6455×4065×5367 | 15125 |

| 2YK2280 | 2200×8000 | 2 | 17.6 | 90-750 | 20 | 30 | 8000×3835×4747 | 10180 |

| 1YK2460 | 2400×6000 | 1 | 14.4 | 150-810 | 20 | 22 | 6050×4035×3005 | 6200 |

| 2YK2460 | 2400×6000 | 2 | 14.4 | 150-810 | 20 | 30 | 6050×4035×4087 | 8013 |

| 3YK2460 | 2400×6000 | 3 | 14.4 | 250-650 | 20 | 37 | 6050×4234×4594 | 10762 |

| 4YK2460 | 2400×6000 | 4 | 14.4 | 250-650 | 20 | 45 | 6050×4266×5073 | 12786 |

We are here to help you with all your needs, whether it be answering questions, providing support, or just getting in touch with us. Our team is always available and ready to help you out.

CONTACT US TODAYPlease tell us your needs such as the capaicty, materials, input and output size, we send the latest price list and quotation to you.

Please tell us your needs such as the capaicty, materials, input and output size, we send the latest price list and quotation to you.