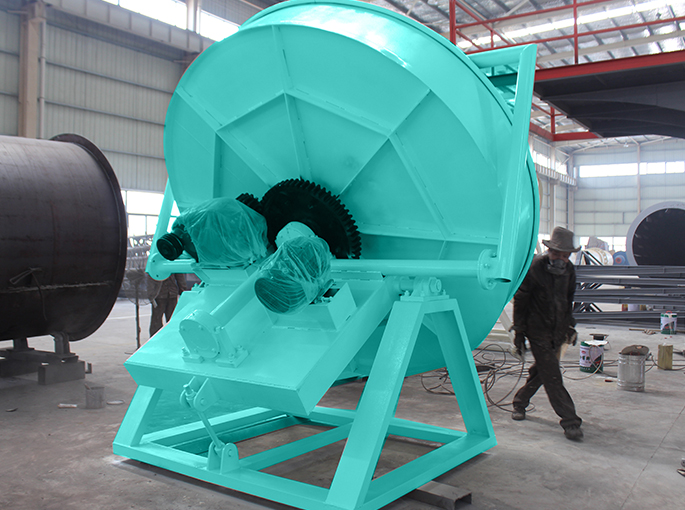

Working principle

All kinds of dry materials enter into the pelletizer from the roof of it, and then are transported to rabbet after degassing and compressing. Then the two rollers rotate towards opposite directions with a same speed, and press the materials. Materials enter into grain making machine naturally because of gravity and tension. After that, the materials will be transported to vibrating screen to be separated. At last, the qualified products will be transported to finished product warehouse or be parked directly. The unqualified materials will come back to feeder machine and be re-crushed. You can adjust the hydraulic system to adjust the pressing force according to the size and strength of the materials. Besides, adjusting the shape of roller surface slot can get different shapes of materials such as, sheet, strip, olive-shaped, flat globular.