- Home

- Product

- Mobile Crusher Plant

- Sand And Gravel Equipment

- Jaw crusher

- Impact Crusher

- Roll Crusher

- Hammer Crusher

- Compound Crusher

- Spring Cone Crusher

- Hydraulic Cone Crusher

- Heavy Duty Fine Crusher

- Trommel screen

- Circular vibrating screen

- Linear vibrating screen

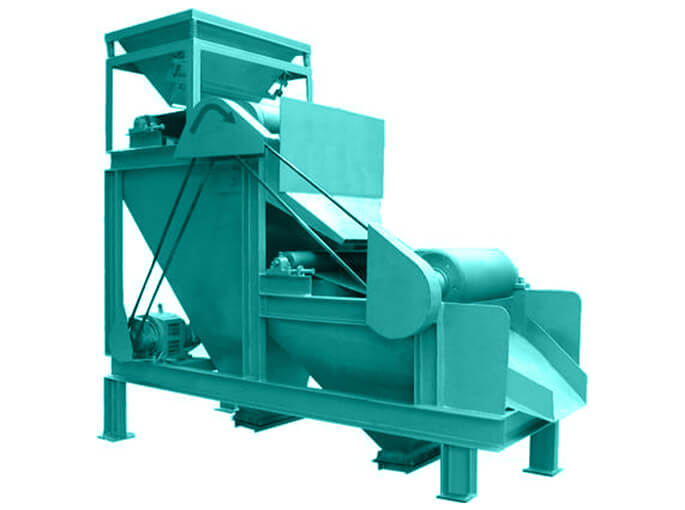

- Screw sand washer

- VSI Sand Making Machine

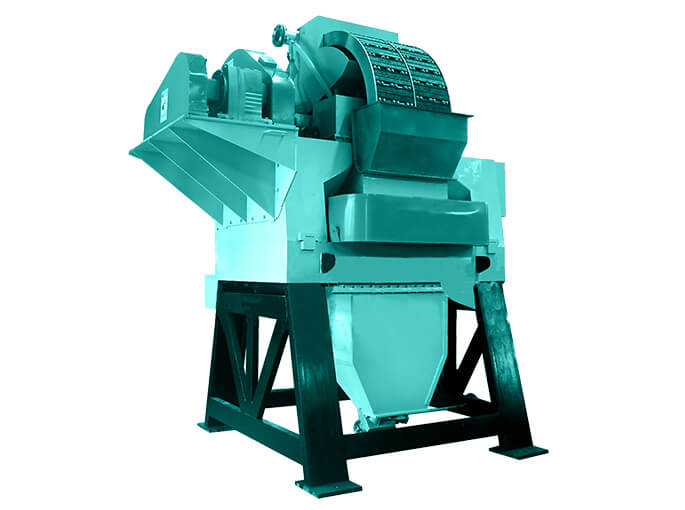

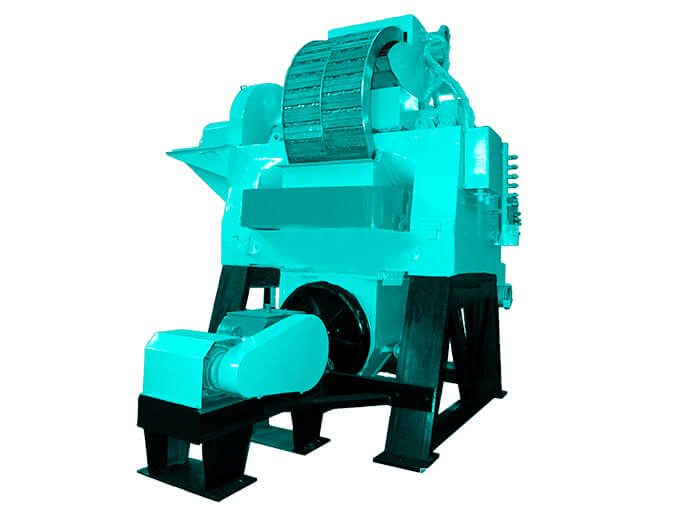

- Sand washing and recycling machine

- ZSW Vibrating Feeder

- Ball Mill Equipment

- Beneficiation Equipment

- Refining Equipment

- Conveying Equipment

- Production Line Process

- Mine Transportation Equipment

- Dryer Equipment

- Rotary kiln Equipment

- Dust Removal Equipment

- Mining Accessories

- About us

- EPC+M Services

- Case

- News

- Contact Us